Description

Technical Specification of Lift

- Special Specification

- Rescue Operation to the nearest landing (optional)

- Door Opening failure rescue operation to the nearest landing.

- Door safety return.

- Opening door waning

- Overload weighing device (warning buzzer/voice guidance)

- Each-floor-stop operation

- Emergency light with self charging and discharging

- LANDIC(emergency landing device)

- Automatic re-leveling device

- Multiple beams door sensor

- Car door pocket sensor

- VONIC (Voice guidance device for car)

- Automatic door dwell time control

- Anti-nuisance call cancellation (judging by timing)

- Anti-nuisance call cancellation (judging by load)

- Behind car call cancellation (cancellation by twice pressing button)

- Automatic car light off

- Automatic car fan off

Technical features of Lift

Brand : FUJIHD (DAZO) ELEVATOR

Country of Manufacture : (JAPAN-CHINA JOINT VENTURE)

Lift Standard : Passenger Lift

Shipping port : “SHANGHAI, CHINA”

Capacity : 1000 kg

Speed : 1.0 m/s

Control system : AC – VVVF (Variable Voltage Variable Frequency) Microprocessor

System, Intellectual Controller.- FUJIHD-Japan.

Drive System : VVVF (Variable Voltage Variable Frequency) FUJIHD

- Smooth starting

- Smooth stopping

- Proper leveling

- Savings of power consumption up to 30%

- Longer life of equipment’s

Conformity : Highest Security With Four-Quadrant Microprocessor Base.

Floor designation : GF-1-2-3-4-5-6(For Seven Stops)

Car travel : 21,000 mm APPROX

Number of stops : 07Floor/07Entrance

Operation : Simplex collective selective control with microprocessor

Signals in car : Digital position Indicator

Signals in all : Digital position Indicator Landings

Pushbutton type : LED with micro movement in car & all floor

Car entrances : Front Opening Only.

Car dimension : Width-Standard Size X Depth- Standard Size X Height-2000 mm (Inside)

Shaft dimension : Width 2250(mm) X Depth-2550(mm)

Overhead : 4000mm (Required)

Pit : 1500mm (Required)

Headroom : 3900mm

Machine room : Direct above the shaft Location

Machine room dimension: 2500mm widthx3400mm depthx2500mm.

Door type : 2 panels Full Automatic, Centre opening for car and all

Landing for lift.

Door dimension : width 900mm (For Center Opening) x Height 21000mm.

Door Sills : Made of anodized aluminum with anti slip grooving

and gliding slots.

Door Configuration :Two panels Side or Centre opening door.

Door Protection : Safety edge.

Power supply :AC 400 volt+10% 3 phase,4 wire earthling, main power AC 220v

(10% 1phase,2 wire, lighting (to be provided by client up to lift machine room with automatic voltage.)

Lighting Supply :220,volt single phase 50hz.

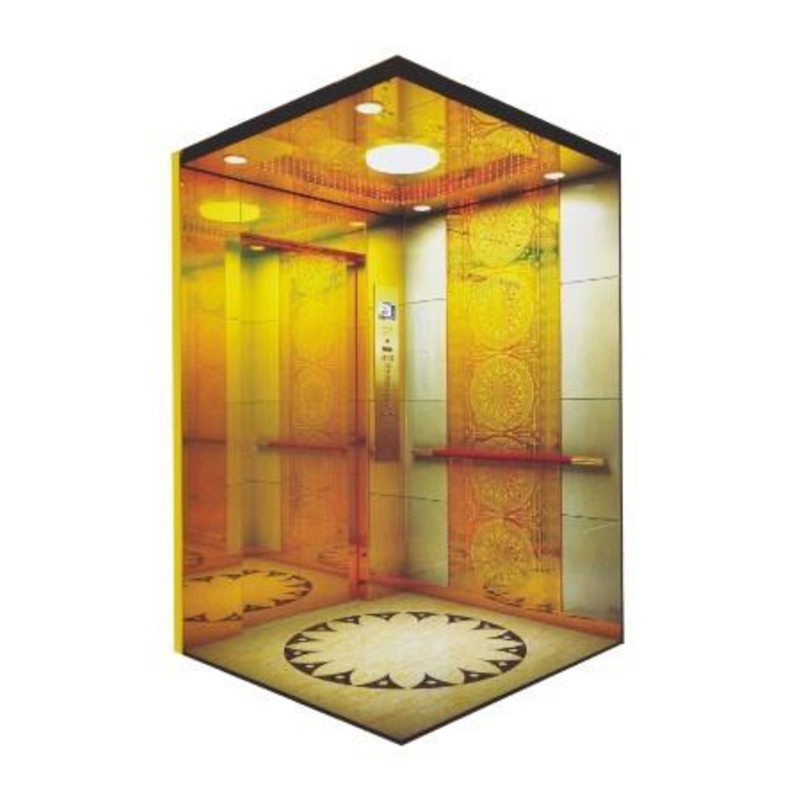

Calling Standard : 171 Cabin Standard.

Ventilation fan : Bower fan

Handrails :4900F

Push button :HBP11

Inverter :FUJI-Japan

Battery Back Up :60 minutes battery back up for emergency light ,Alarm and

intercom system in case of power failure. Tickle Charge provided.

Car Push buttons :GF—5 car call buttons, Alarm push, Door re-open push, Blower fan

Switch, car operating panel.

Car signaling : Digital position indicator ,Direction indicator,calls registered

indicators in call buttons, overload indicator, car Arrival Gong.

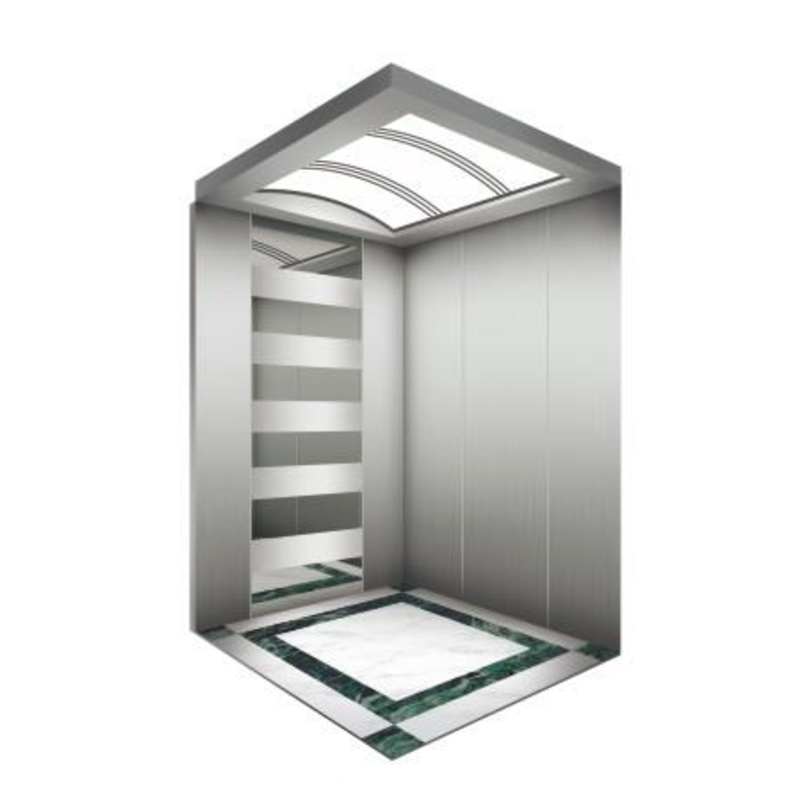

Car Ceiling & Lighting: Suspended Standared perforated in stainless steel with indirect glare free fluorescent lighting.

Car door operator : Heavy-duty car door operator will be provided for automatic,2 panels Side or Center opening,800mm. Clear (if allowed by actual Shaft Width).

G.F: Landing door fame : Architraves Stainless steel mirror finished.

Safety/ Additional fittings: 1) Emergency light 2) Intercom system 3)

Car lights & fans (4) Full Height Photo Sensor

(5) U.P.S. with 1.5 Hrs Power Back up.

(6) Speed Governor(Emergency power off & stopped

the lift) 7. Barger (talking) full set.8.Cabin Buffer.9.Overload Devise.

Car/Cabin : Stainless steel Etching Mirror & rear wall

Stainless steel Super Mirror/ Etching Mirror with Stainless steel Hand rails(Sample).

Car door finish : 2 panels Full Automatic, Stainless steel Hair Line

finished(Sample)

Landing Doors : 2 panels Full Automatic, Main Landing door wide jam ,Etching Mirror and all other landing doors narrow jam taintless steel hairline finished(Sample)

- Motor : 9Kw ± 10%,(Gearless-FujiHD-Origin Japan-China),180 SPA ,With thermal Protection.

- Final limit switch : Disconnects the controller electric supply of the car

over travels either the top or bottom terminal landing

- Evacuation : During power failure the car will be manually moved

to the nearest higher or lower landing and the doors will be opened to facilitate evacuation of passengers.

- Traveling cable : Flat l round type with required size and number in

machine room and the shaft in plastic conduits.

- Car & counterweight guide: Special T – Guide rails machined to a high degree of fineness ensure the smooth running of the elevator.

- Suspension ropes : “SEALE” construction of bright steel wires with fiber

cores, the rope construction is constructed to shut the lift down if one or more suspension ropes become slack.

- Buffer : If the car travels beyond the lowest floor or above the

top floor the buffer reduces the shock of traveling cabin & counter weight frame at the bottom of the shaft.

- Maintenance control : Car stop station with an initiating switch, one up and

one down button and one stop button.

- Pre limit switch : When the magnetic conduct fail to take slow speed in

top and bottom floor, there will have a pre limit switch (Electro mechanical switch) to help take slow speed in top and bottom floor and the lift stops smoothly in the floor level.

- Final limit switch : If the car travels above top floor level or below bottom

floor level it cuts off the main power of motor and stops functioning the lift.

- Phase failure : If any phase of the main power supply is cut off

(absent) , the protection switch does not provide supply to control circuit and the lift does not start.

- Phase reversal : If the phase are changed by any external subject such

as PDB etc, for the safety of the lift & its passenger this protection switch off the main power supply to the control circuit and the lift does not start.

- Emergency unlocking : All landing doors provide key system for emergency

unlocking for landing for evacuation as well as for maintenance with a special key.

Landing door sills : Extruded hard aluminum door sills with anti skid grooving for

Smooth, safe and proper movement of door Panels.

Landing push button: Stainless steels push plates, single buttons at 2station terminal floors

And 2 buttons in all intermediate for directional call options call options.

Landing signaling :Digital position indicators, direction indicators, call registered indicators, o

Out of device indicators in all floors.

Car guide rail :Standard machined T-section Steel,65x65x10mm.

Counter weight guide rail: Standard machined T-section Steel,65x65x10mm.

Roping :5x10mm.(steel rope1:1 roping Standard seal standard seal standard

8×19+1FC

Traveling cable :Special standard flat cable suitable for lift system.

Rope : Seale

Counter weigh :Cold Drawn.

Pre –limit Switch: Pre-limit switch will be placed in the shaft at tope and bottom terminal

Floor which will reverse the direction for further at the terminal floors once

cut

Terminal limit switch Buffer spring: Final Limit switch will be placed shaft at the terminal

Floors beyond the normal travel to stop the lift in case over travel spring

Buffer will be also Provided.

Over-speed governor: The lift will be equipped with over speed safety governor which will act

In case of over speed in the downward direction to stop the lift.

Safety Gear :The lift will be equipped with instantaneous safety gear at the top of the

Lift cabin which in conjunction with over speed governor will clamp the lift to the guide rails in case of over speed.

Speed Governor :Apart from mechanical clamping of the lift in electric switch case over

Speed,the speed governor will be equipped with and electrical switch to

Cut off the power to the controller and motor incase of emergency.

Car Door Lock Electric:The lift shall be equipped with double electric lock contact

Contacts in the car door.If the car door is not closed properly the

Lift shall not run.

Landing Doors lock:All the landing doors shall have double electric contacts electric

Lock contacts in case any of the landings door in not properly closed

The lift hall not run

Car Inspection Panel: The lift shall have car top inspection panel with maintenance run

Option and emergency stop button to facilitate maintenance operation

Door Coupling Device:The car door operator shall be equipped with secure coupling

Device to synchronize the respective landing door in the door Zone.

Evacuation Device:Manul evacuation device provided,automatic rescue device as Optional.

Safety Door Hanging Device:All the landing doors shall have proper and safe hanging

Device to prevent sliding of doors beyond normal limit.

Emergency Brake release:The electro-mechanical brake in the geared lever machine

Will equipped with a release lever to facilitate emergency

Rescue operation.

Boltage stabilizer:If the power will high and low than its done original power supply

To motor and control(Optional).

Full Car By Pass Indicator:Landing indicator shows it is in the state of by pass.

Independent Travel:All hall call signals will be cancelled elevators only respond

To the car call.

03.Safety Devices and Special Features:

- Retractable both safety shoe for the full height of the door which reopens the door

When it is obstructed by any object while closing.

- Emergency Car light,which will light during 30 minutes power failure and charged

By trickle charger.

- Inter-Phone and alarm buzzer system among car ,machine room &lobby.

- Audible Overload protective device.

- Fan provided for forced quiet ventilation from car top concealed by drop ceiling.

- Emergency stop and call button provided on car operating panel board.

- Light and fan switch provided at the switch box of car operating panel board.

- Inspection station provided on the top of the car.

- Up and down directional arrows provided on the car operating panel board.

- Photocell (Multi-photo+1-side) shall be provided.

- Emergency Light (with self charging & discharging).

- Photoelectric Type Door Sensor.

- Multiple Beams Door Sensor

- Behind Car Cancellation.

- Every Floor Stopping Operation.

- VONIC(Automatic Voice Announcement System).

Terms & Condition:

DELIVERY: As per payment schedule.

INSTALLATION & COMMISSIONING : The lift shall be installed and commissioned within 60 days ± 10 days from the date of delivery.

- Order Processing & L/C Opening: Within 07 Days from the Date of Work order and of 1st Installment payment.

- Production& Shipment :Within 60 (sixty) days from the date of receipt of L/C by our Principal.

- Ocean Transit Time :Within 20 (twenty) days from the date of sailing.

Clearing &Delivery at Site: With in 7 (seven) Days from the date of berth of the Vessel at Chittagong port.

- Shipment: Guangdong , CHINA.

Free maintenance: Twelve month from the date of commissioning of the lift.

- Offer Validity : 30 Days from the date of issue.

- Contractual Maintenance: After Expiry of Free Service Period Lift Can be Maintained by us Against Service & Maintenance Contract Between the owner and us at a Monthly Service & Maintenance Charge Of taka 3500/- (Three Thousand five hundred) Only Per Month, Per Lift and The Contract Can be Renewed For Further Periods on Mutual Agreed Terms.

EXCLUSIONS:

MACHINEROOM CONSTRUCTION: *Location direct above the shaft *Door for entrance of machine room * Hook for lifting at middle, *A fan for cooling *Arrangement of water proof * Trap door above the top floor.

POWER ARRANGEMENT *Three phase line of 400 volts in machine room , *Necessary bus bar, ducting, MCB etc as per requirement for feeding power to the lift. * Circuit breaker in machine room and ground floor.

FINANCIAL OFFER

3) Sample price of the lift as follows:

| OPTION-01 | Description | Price at BDT. |

| Bed Lift.

( With ARD & 1set 30KVA Voltage Stabilizer . |

FUJI HD(DAZO) ELEVATOR (Sino-JAPAN JOINT VENTURE), Passenger lift of 1000 Kg13-Person/7stops, Car/Cabin& Main Landing Door- Etching Mirror/ Hair line finished, Doors Mechanism- Panasonic-Japan., Control-A/C- VVVF-FUJIHD-Origin-Japan. Motor-9 KW, (Gearless – FUJIHD–Origin-Japan-China).Speed- 1.0 m/s ,, COP/LOP –FUJI HD-China , Guide Rail-zinda-China, (Built In Volt Guard) . |

25,00,000

|

| Price are including Govt, duty, tax, supply, installation, testing and commissioning. | ||

In Word: Twenty Five Lac Taka Only.

4.The supplier agrees to give the REPLASEMENT GUARANTY 03 (three) Years (For Motor &

Controller) And 01(One)) Years Warranty Others Parts from the date of commissioning.

Warranty covers replacement of any defective parts due to manufacturing defects and comes from

bad workmanship. The warranty will not be enforceable if any parts become damage for ill

Handling & electrical over / low power supply.

- The Purchaser agrees to make ready the sites as follows:

- a) All civil work required to ready the shafts and machine rooms will be done by the Purchaser.

- b) The purchaser will provide electrical power fine of 400 volts, 3 phase, up to machine room, circuit breaker of 63 amps, and all electrical arrangements including MDB and SDB necessary for the lifts.

- c) The purchaser will provide a stare at site under their own control to keep the

materials ‘in a suitable condition.

- Free Servicing : 01 year from the date of trial run operation.

- That this agreement shall be executed in two counterparts, one for the Supplier and the other

for the Purchaser.

- That if due to Force Measure, such as war, invasion acts of god revolution, civil riots and acts of government, the performance if the agreement could not be carried out, the time for the performance of such obligation shall be extended for the period for which circumstances and their effects remains enforce.

PAYMENT SCHEDULE (INTAKE-BRAND)

| Installments | Amount | Payment date |

| first | 40% of sales value | During signing the agreement to open the L/c |

| Second | 50% of sales value | To retire the shipping documents from bank |

| Third | 05% of sales value | During delivery the materials from port for INSTALLATION & COMMISSION. |

| Forth& Final | 05% of sales value | Within one month from the date of TEST RUN operation For Handover. |

On the above all, we are always at your service.

Reviews

There are no reviews yet.